Overmolding Services

Multiple Types of Overmolding To Best Suit Your Project

Overmold Express specializes in high-quality overmolding services, providing innovative solutions that enhance the performance and durability of your products. Our expert team leverages advanced techniques to create seamless, reliable bonds between different materials, ensuring optimal functionality and aesthetic appeal.

Material Options

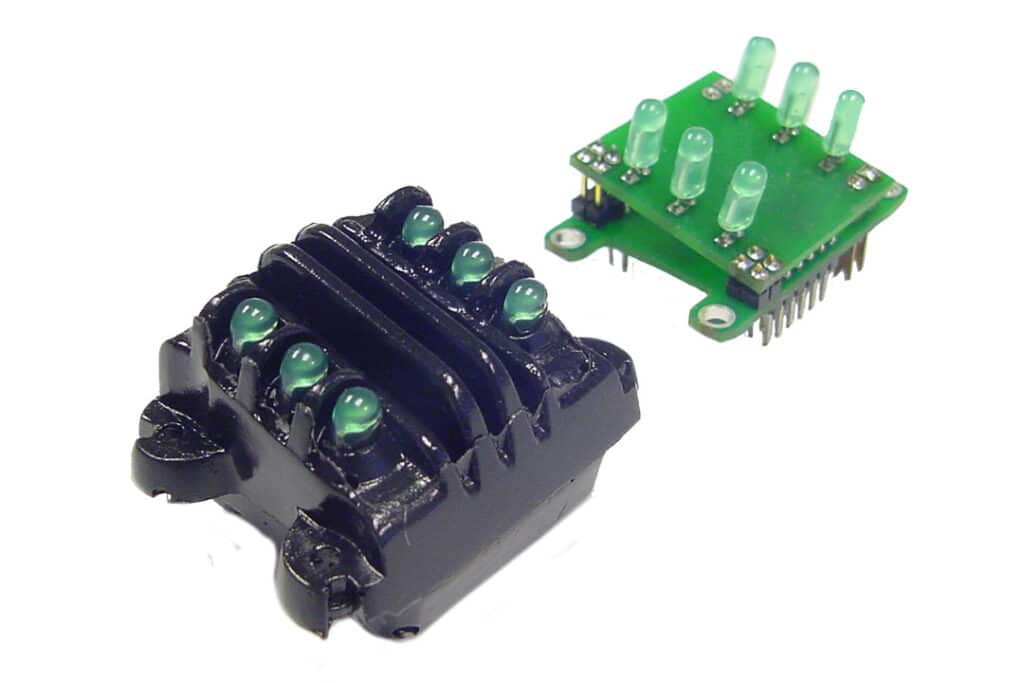

- Translucent or colored

- Optically clear

- Thermally conductive

- Rigid or flexible.

| Temp. Range (Cels) | Avg Pressure (PSI) | Avg Cycle Time | Avg Material Costs / lb | ||

| Low Pressure Overmolding | LPO | 200 – 240 C | 200 | 30 – 60 secs | $17 |

| Thermoset Overmolding | TSO | 24 – 65 C | 80 | 60 – 300 secs | $10 |

| Liquid Silicone Overmolding | LSR | 24 – 65 C | 80 | 60 – 300 secs | $15 |

| Standard Injection Molding | IMM | 200 – 280 C | 30000 | 10 – 20 secs | $4 |

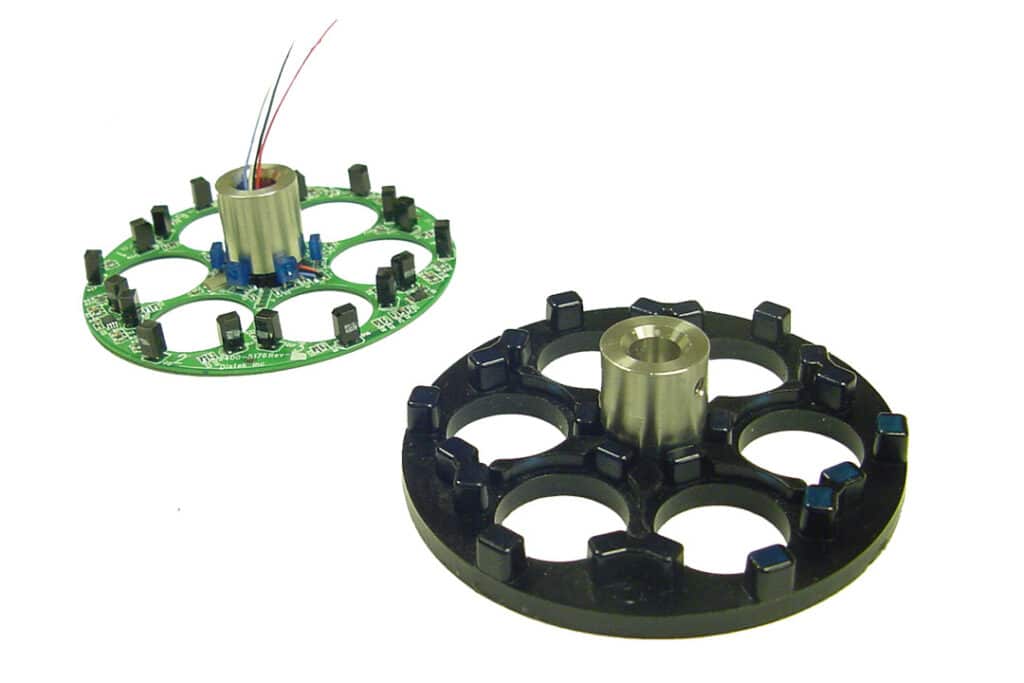

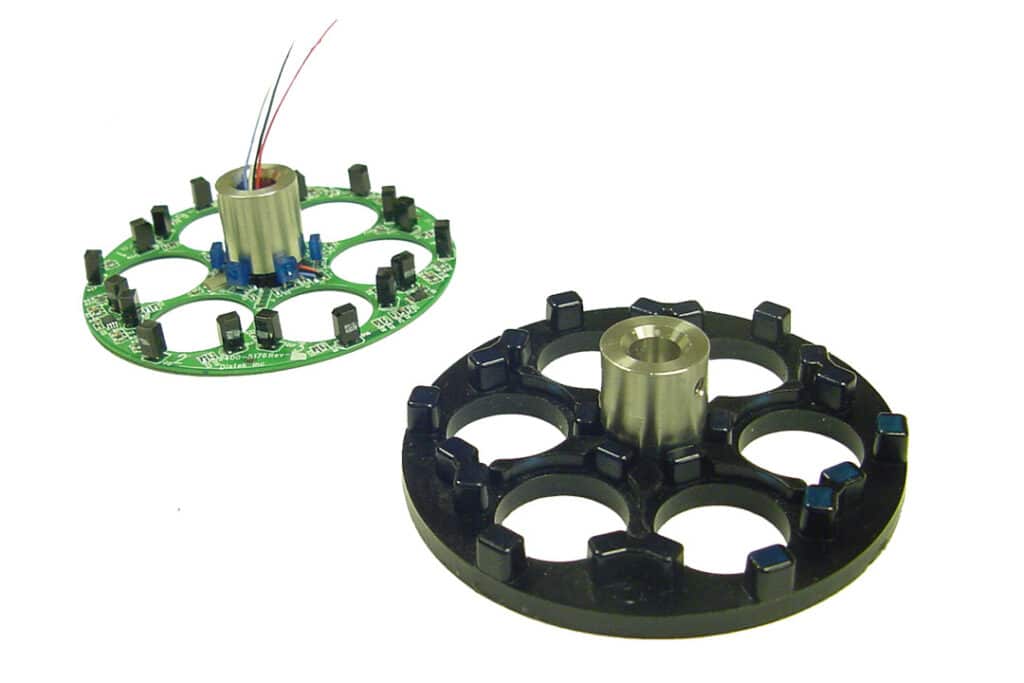

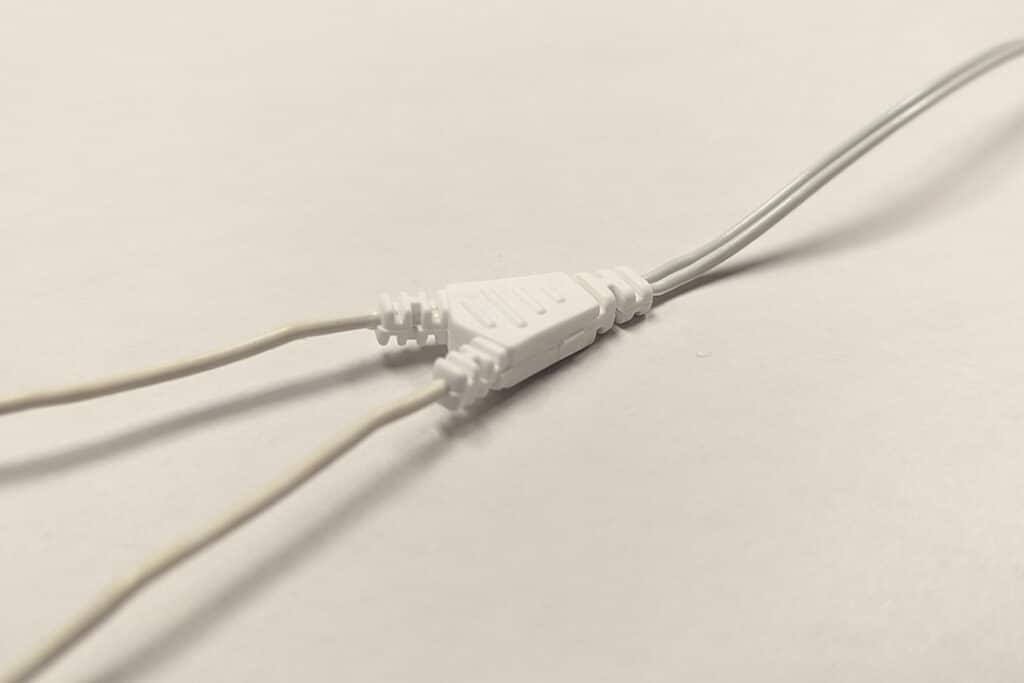

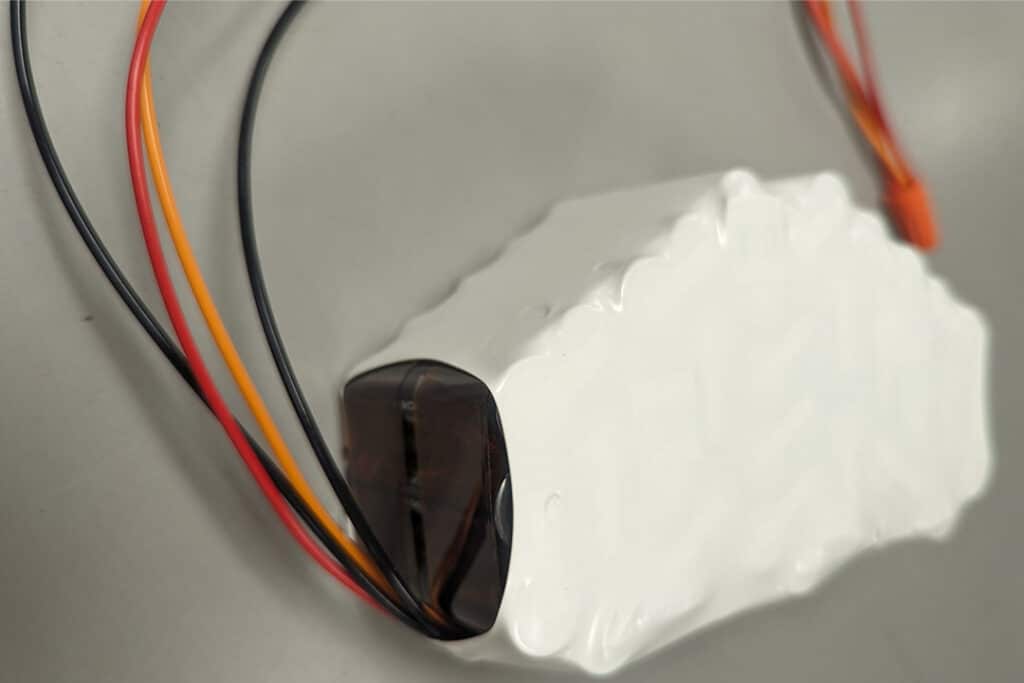

Low Pressure Overmolding

Low Pressure Overmolding (LPO) is a process commonly used to encapsulate and protect electronic components, such as circuit boards, switches, and sensors.

Purpose

LPO aims to safeguard electronics against moisture, dust, dirt, and vibration.

Materials

During LPO, polyamides (plastic) are melted in a tank and then pumped into specially designed overmold tooling. These polyamides act as the protective layer around the components.

Temperature Range

The typical LPO process involves temperatures between 250 and 450 Fahrenheit (121 to 232 Celsius).

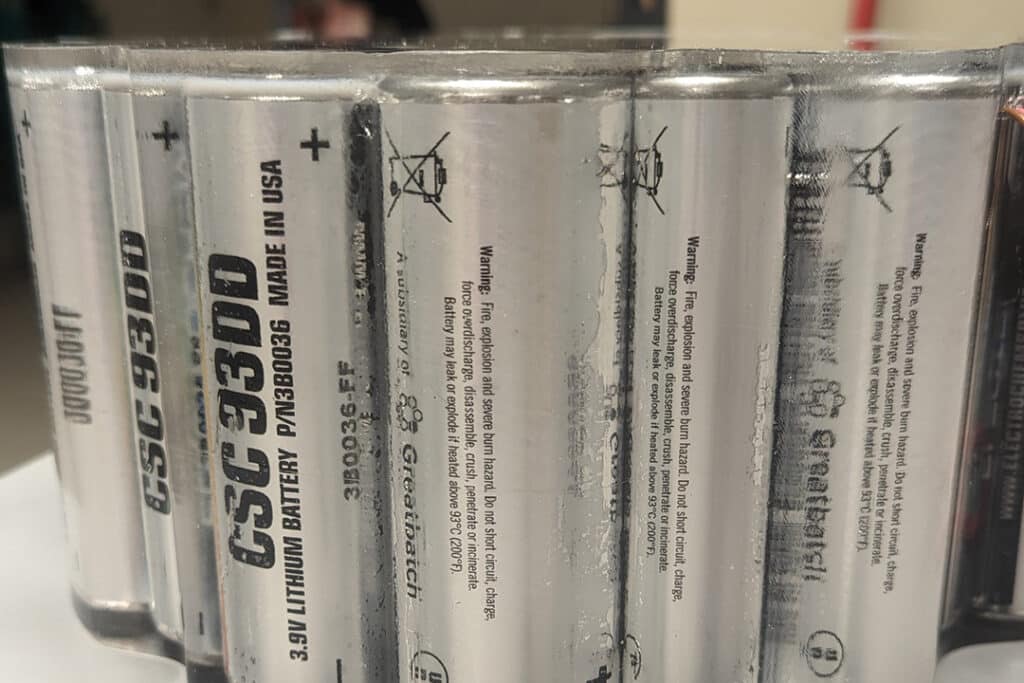

Battery Considerations

LPO is generally safe for most components, including LED assemblies, wire harnesses, and buttons. However, this process can damage batteries because the temperature of the material during injection is higher than the maximum service temperature for most batteries. Some batteries and packs can be molded with this process if they are shielded from the heat with a premolded plastic cover. If the premolded cover isn’t feasible, then we would recommend a thermoset overmolding process.

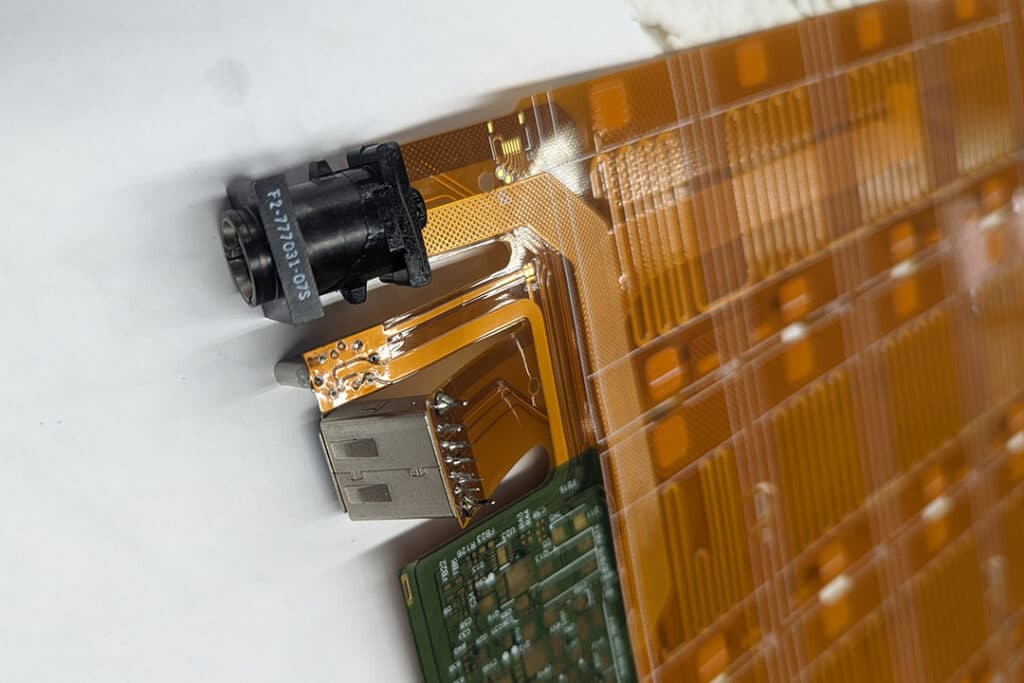

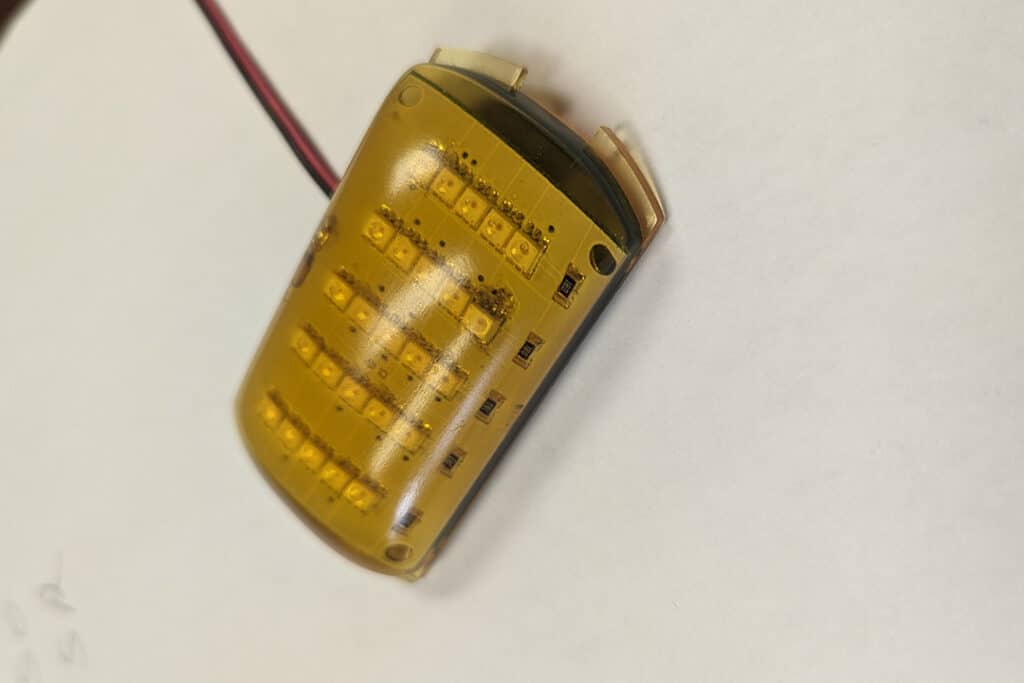

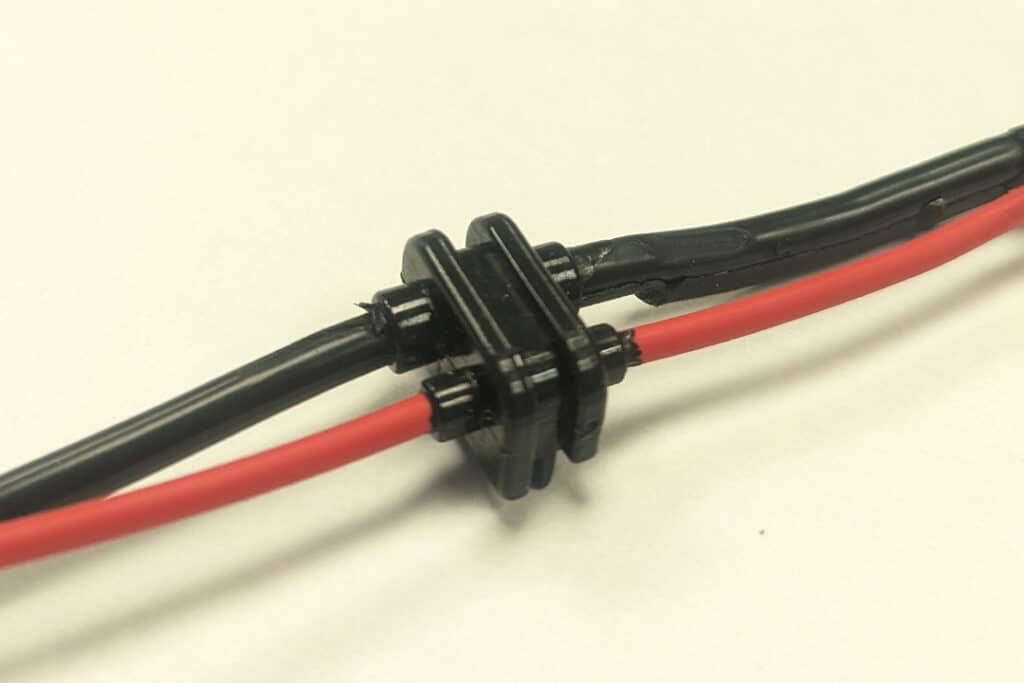

Thermoset Overmolding

Thermoset Overmolding (TSO) is a process commonly used to encapsulate and protect electronic components, such as circuit boards, battery packs, switches, LEDs, and sensors. Here are the key points:

Purpose

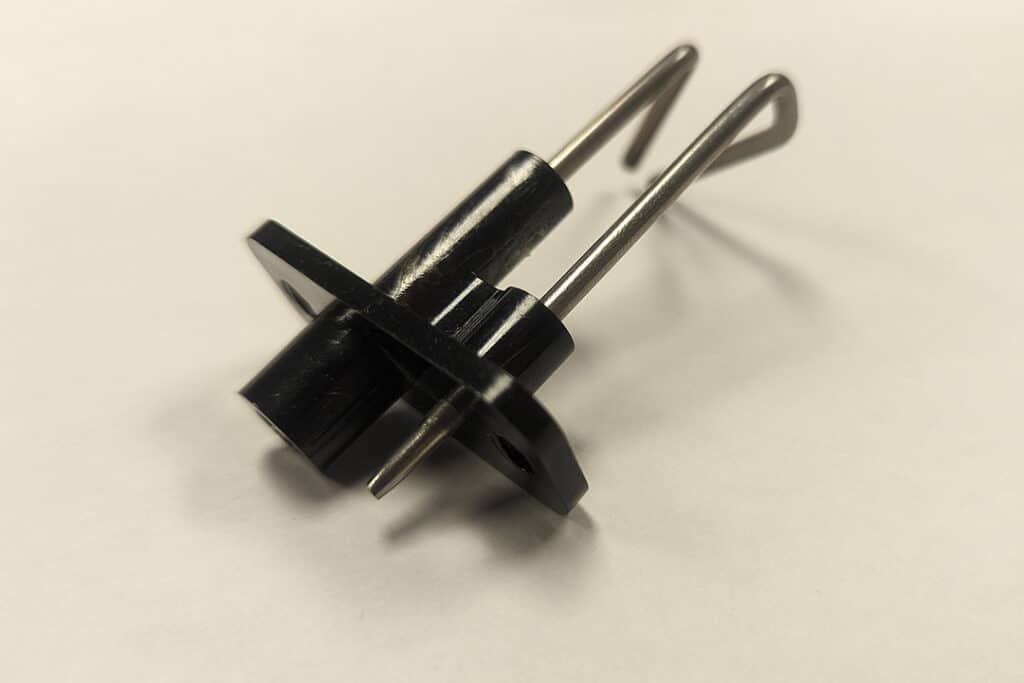

TSO safeguards electronics against moisture, dust, dirt, and vibration, and is used for sealing connectors, molding grommets, and providing strain reliefs.

Materials

TSO materials are liquid at room temperature, enabling safe overmolding of PCB assemblies, sensors, wire harnesses, electronic devices, batteries, and LED components.

Low Pressure & Low Temperature Process

TSO operates at very low pressures, sometimes as low as 1 PSI, allowing large or sensitive assemblies to be overmolded without issues. Materials are processed at 70 to 150°F, making it safe for batteries and sensitive components.

Material Options

TSO offers a range of properties, from soft gels to rigid plastics, including thermally conductive, optically clear, skin-safe, UL 94 V-0 approved, high-temperature resistant, USP Class VI for medical devices, easily colorable, and UV resistant.

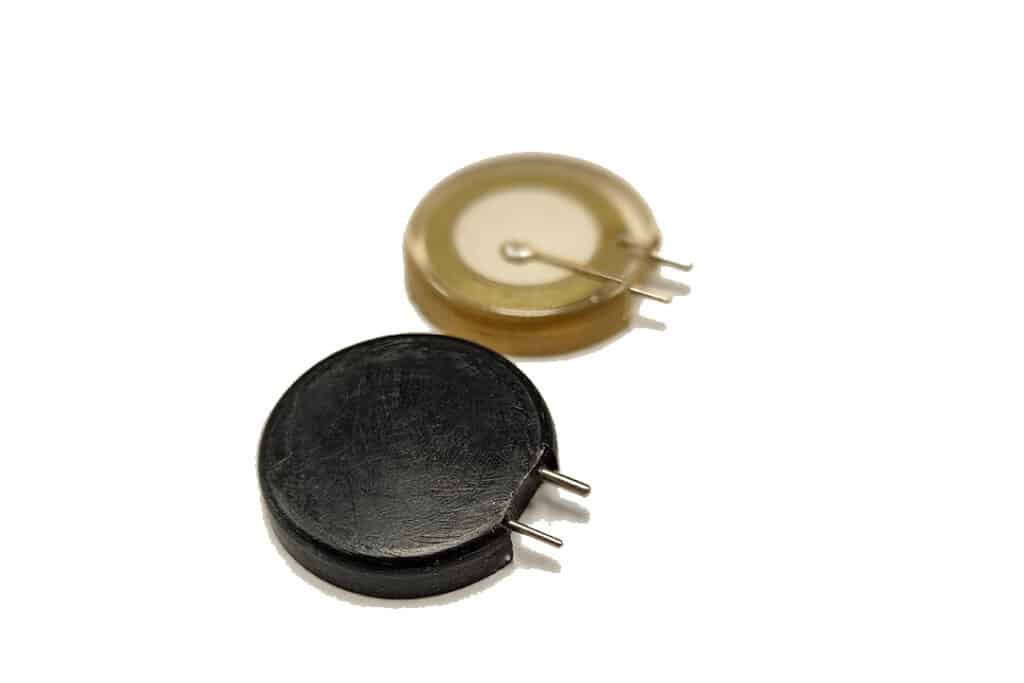

Safe for Batteries

TSO is the only process safe for direct molding over batteries and battery pack assemblies due to its low temperature and pressure.

One-Step Solution

TSO can hermetically seal your product, provide a functional casing with buttons and visible LEDs, and include strain relief for cables in a single step.

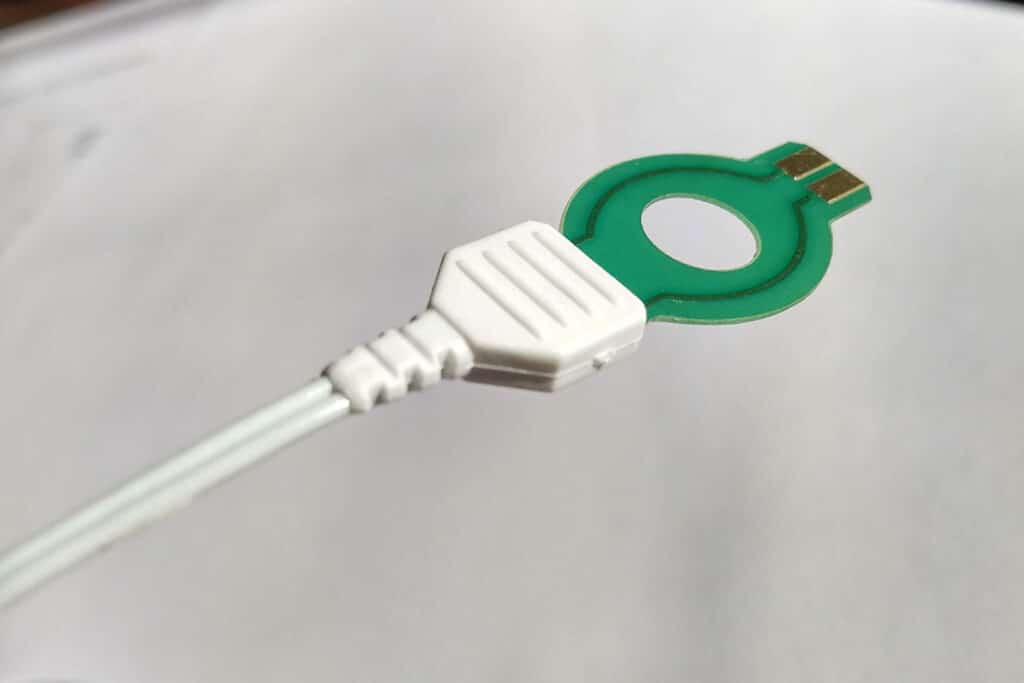

Liquid Silicone Rubber Overmolding

Liquid Silicone Rubber (LSR) Overmolding is an advanced technique involving the injection of liquid silicone rubber onto pre-existing substrates like PC boards, batteries, connectors, and specialized medical devices.

Safe for Electronics

LSR overmolding is performed at low temperatures and pressures using specially formulated materials, ensuring safety for all electronic components and batteries.

Integrated Components

The LSR fills the designated area of the substrate, forming a complete integrated component.

Temperature Range

The typical LPO process involves temperatures between 250 and 450 Fahrenheit (121 to 232 Celsius).

Advantages

Enhanced Properties: LSR components can endure high temperatures and pressures, making them suitable for automotive, medical, and industrial applications. Ideal for parts with tight tolerances.

Life Sciences: LSR’s biocompatibility, hypoallergenic properties, and odorless/tasteless nature are crucial for medical devices, respiratory equipment, and syringes.

Automotive: LSR overmolding provides temperature-resistant seals for engine components, headlights, and electrical connectors, preventing water damage to vehicle systems.

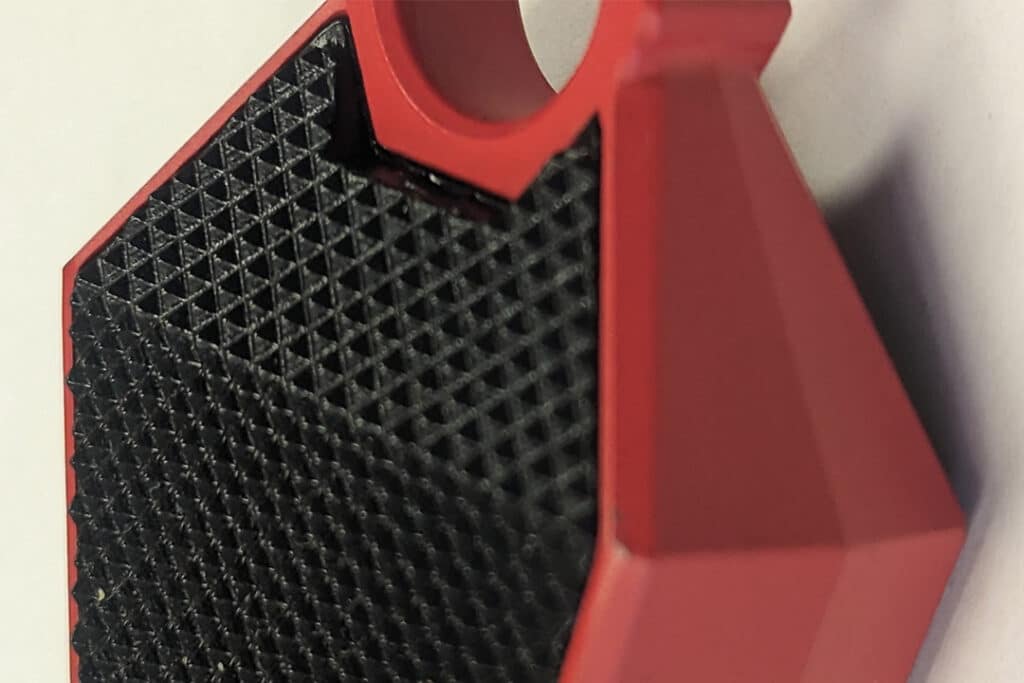

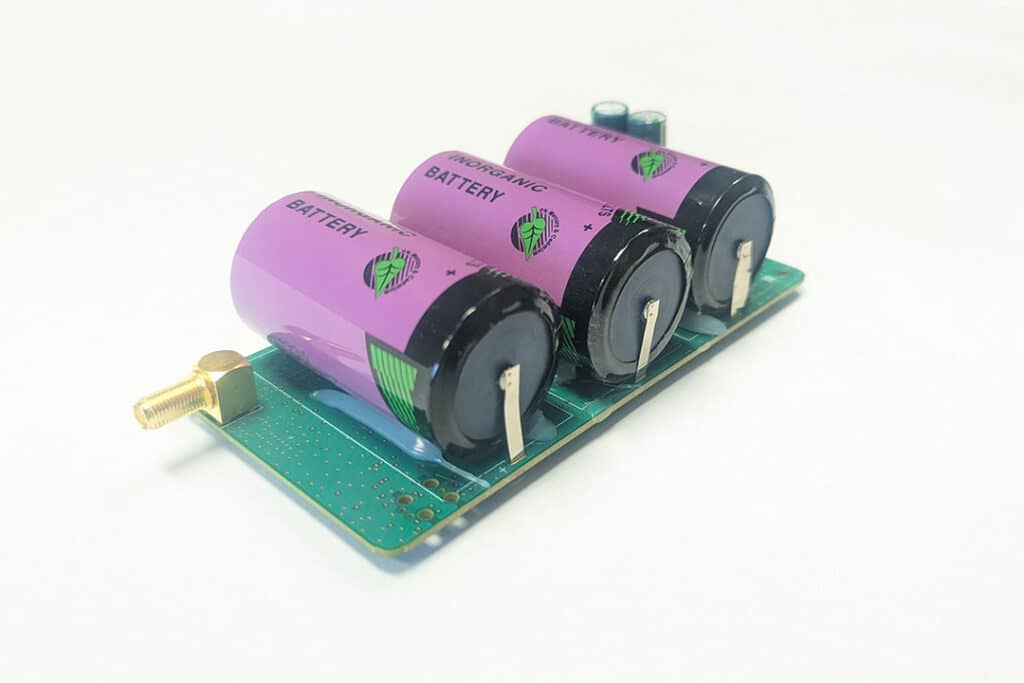

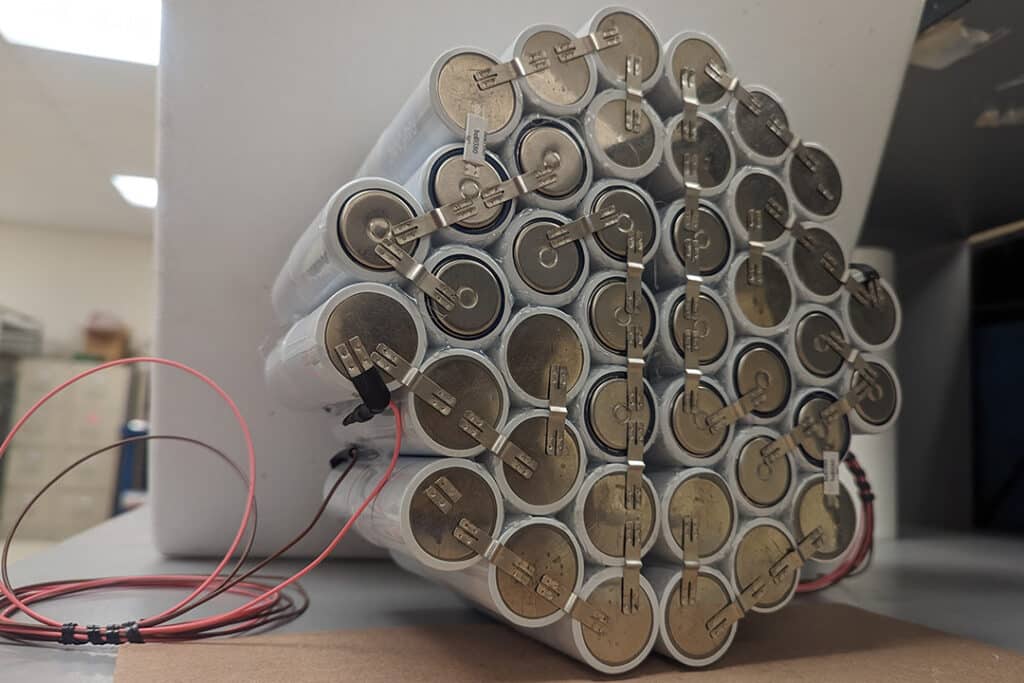

Battery Pack Overmolding

Overmolding batteries can offer several benefits, especially in terms of protection and durability. Here are some reasons why overmolding is commonly used for batteries:

Physical Protection

Overmolding provides a protective layer around the battery, shielding it from external impacts, moisture, and dust. This helps prevent damage during handling, transportation, and usage.

Enhanced Durability

The overmold material (usually a thermoset elastomers) adds strength and resilience to the battery. It can withstand mechanical stress, vibration, and temperature variations, extending the battery’s lifespan.

Improved Thermal Management

Overmolding can help dissipate heat generated during battery operation. By encapsulating the battery, it enhances thermal conductivity and prevents localized hotspots, which can be critical for battery safety and performance.

Chemical Resistance

Overmolding materials can resist exposure to chemicals, solvents, and corrosive substances. This protects the battery from chemical degradation and ensures long-term reliability.

Electrical Insulation

Overmolding acts as an insulating barrier, preventing electrical shorts caused by accidental contact with conductive surfaces. It reduces the risk of short circuits and enhances safety.

Customized Shapes and Designs

Overmolding allows manufacturers to create custom shapes and designs for batteries. This flexibility is useful for fitting batteries into specific spaces or integrating them seamlessly with other components.

Keep in mind that while overmolding offers advantages, it’s essential to consider factors like material selection, design, and cost. Additionally, different battery chemistries (such as lithium-ion) have specific requirements for overmolding to ensure optimal performance and safety.