Turnkey Battery Packs Assembly

battery packS

We Make Custom Battery Packs

Many products we mold use batteries and for this reason, we have created a large assembly department capable of performing many of the necessary tasks required prior to molding electronics.

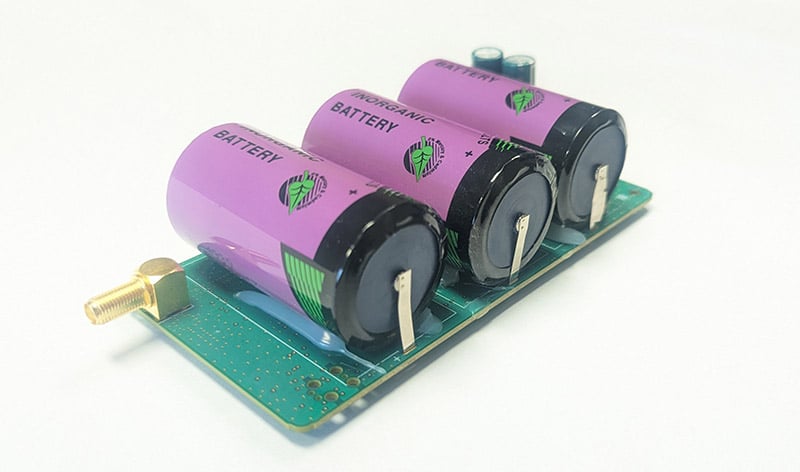

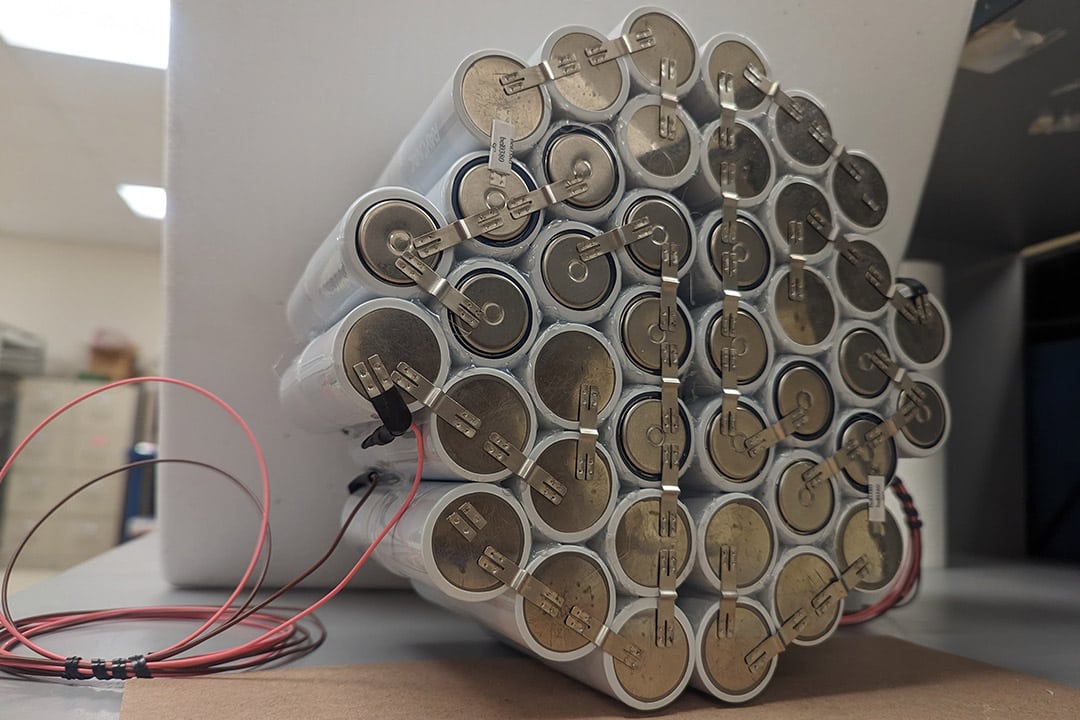

Battery Pack Assembly

Our assembly area has extensive capabilities in assembling complete battery packs that are ready to connect to electronic assemblies prior to molding.

- Resistance spot welding

- Connecting wire leads to battery terminals

- Shrink-wrapping

- Assembling thermal overload protection

- Soldering

- Manufacturing custom nickel battery tabs

- Charging and discharging battery packs

Battery Overmolding

Overmold Express provides Overmolding, potting and encapsulating of batteries and battery packs. These processes will help protect them from shock, vibration, moisture, and other environmental factors. See our Overmolding batteries page for more details.

Battery Potting, Encapsulation and Casting

Potting is the process of covering an electronic device inside an enclosure with an adhesive compound for the purpose of providing resistance to shock and vibration as well as creating a seal against moisture and dust. Potting compounds are also used to aid with electrical insulation, flame retardency and heat dissipation.

The common potting compounds are polyurethane, epoxy, and silicone. These materials vary in hardness from soft rubber to rigid plastics, and are designed to withstand many different types of environments. Determining which compound is best for your application will be based on operating and environmental conditions and physical properties required for the product.

Encapsulation and Casting are similar processes that can be performed with similar materials as potting although we use a low cost removable mold. This eliminates the need for a plastic shell or case to contain the adhesive during the curing process. Most of our molding services can be incorporated into your finished battery pack to make it water proof and safe for hazardous environments.

Common battery chemistries we work with are:

- Lithium-thionyl chloride

- Lithium manganese dioxide

- Lead-acid

- Nickel cadmium (NiCd)

- Nickel metal hydride (NiMH)

- Lithium polymer (LiPo)

- Lithium-ion (Li-ion)

- Lithium-ion polymer (Li-ion polymer)

Connecting battery packs to electronic assemblies

Many of the electronics we overmold need batteries connected prior to the overmolding process. We perform soldering on small and heavy gauge wire, along with soldering and brazing of threaded terminals and lugs to solder pads and terminals.

Electrical Testing

Testing is an equally important part of our process. We perform testing after overmolding to confirm that all products are working correctly. We test the following:

- Continuity

- Voltage

- Confirm RF

- Hipot