Thermal runaway is a process where an increase in temperature causes a further increase in temperature, leading to a potentially destructive positive feedback loop. This phenomenon is primarily observed in chemical reactions and electrical systems, but can also occur in mechanical and biological contexts. Understanding the mechanisms behind thermal runaway is crucial for ensuring safety, reliability, and longevity in a wide range of applications, from the batteries in your smartphone to the complex industrial processes that power modern society.

At its heart, thermal runaway is a self-accelerating phenomenon. Imagine a small fire starting in a dry forest. The initial flames heat the surrounding wood, which then ignites, spreading the fire further and faster. This is analogous to thermal runaway. In chemical reactions, if the rate of heat generation exceeds the rate of heat dissipation, the temperature rises. This elevated temperature, in turn, increases the rate of the reaction, leading to even greater heat generation. This cycle continues, often escalating rapidly, until the system is depleted of reactants, fails mechanically, or is brought under control. For advanced electronics protection, consider using thermally conductive overmolding to enhance heat dissipation and durability.

Positive Feedback: The Engine of Escalation

The defining characteristic of thermal runaway is positive feedback. In this scenario, a change in a variable (temperature) triggers a response that amplifies the original change.

The Role of Reaction Kinetics

The rate of most chemical reactions is highly dependent on temperature. This relationship is often described by the Arrhenius equation, which shows an exponential increase in reaction rate with increasing temperature. As thermal runaway begins, this temperature dependence becomes a powerful driver, ensuring that each increment of heat generation leads to a proportionally larger subsequent heat generation.

Heat Dissipation Limitations

For a reaction to remain stable, the heat it generates must be effectively removed by its surroundings. This heat dissipation is influenced by factors such as the surface area of the system, the thermal conductivity of its components, and the ambient temperature. When heat dissipation is limited, for instance, in a confined space or with poor insulation, the generated heat accumulates, fueling the runaway process.

Thermal runaway is a critical phenomenon that can occur in various electronic devices, particularly in batteries, leading to catastrophic failures if not properly managed. For a deeper understanding of how encapsulation techniques can help mitigate such risks, you can refer to the article on potting and encapsulation methods found at this link. This resource provides insights into how these protective measures can enhance the safety and reliability of electronic components, ultimately reducing the likelihood of thermal runaway incidents.

Triggers and Initiating Events

While thermal runaway is a process, it requires an initial trigger to set it in motion. These triggers can be varied and often arise from system imperfections, external influences, or operational errors. For us to appreciate the danger, it’s important to recognize what can kickstart this chain reaction.

Internal System Defects

Sometimes, the seeds of thermal runaway are sown within the system itself. These are often subtle flaws that can be exacerbated by normal operating conditions or minor disturbances.

Material Degradation

Over time, materials can degrade due to wear, chemical attack, or environmental exposure. This degradation can lead to increased internal resistance in electrical components, reduced thermal conductivity, or the formation of reactive byproducts, all of which can lower the threshold for thermal runaway. For example, the electrode materials in a battery can degrade over repeated charge-discharge cycles, increasing the risk of internal short circuits.

Manufacturing Imperfections

Even with stringent quality control, manufacturing processes can sometimes introduce defects. These might include microscopic cracks in separators in batteries, inconsistencies in the mixing of reactive chemicals, or faulty soldering in electrical circuits. These imperfections can create localized hot spots or pathways for unintended reactions to begin.

Contamination

The presence of unintended substances within a system can act as catalysts for unwanted reactions or create pathways for short circuits. In chemical processes, a small amount of a contaminant can significantly alter the reaction kinetics and increase heat generation. In batteries, even trace amounts of moisture or metallic particles can lead to internal failures.

External Disturbances

Beyond internal flaws, external factors can also provide the necessary spark for thermal runaway. It’s like an unexpected gust of wind fanning a nascent flame.

Overcharging and Over-Discharging (Batteries)

In rechargeable batteries, operating outside their designed voltage limits can lead to dangerous conditions. Overcharging can cause the electrolyte to decompose, generating gas and heat. Over-discharging can damage electrode materials, increasing the risk of internal short circuits during subsequent charging.

Mechanical Stress and Damage

Physical impact or excessive stress can compromise the structural integrity of a system. In batteries, physical damage can lead to internal short circuits. In chemical reactors, mechanical failure might allow reactants to mix in an uncontrolled manner.

Elevated Ambient Temperatures

Operating a system in an environment that is already at a high temperature reduces its ability to dissipate heat. This lowers the temperature difference between the system and its surroundings, making it more susceptible to thermal runaway if any exothermic process begins.

Electrical Overloads

In electrical systems, exceeding the designed current capacity can lead to resistive heating. If this heating is significant enough and cannot be dissipated, it can initiate thermal runaway in components.

Manifestations in Specific Technologies

The consequences and specific triggers for thermal runaway vary significantly depending on the technology involved. Understanding these nuances is key to implementing appropriate preventative measures.

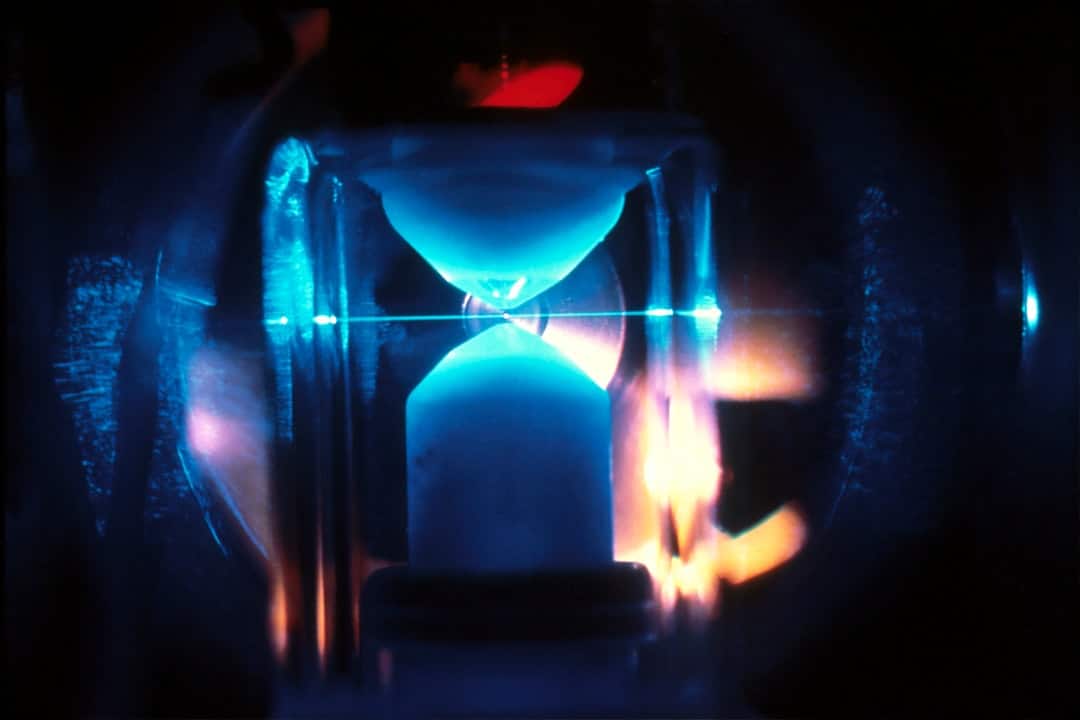

Lithium-Ion Batteries: The Ubiquitous Concern

Lithium-ion batteries are a prime example where thermal runaway is a well-documented and significant safety concern, largely due to their high energy density and the flammable nature of their electrolytes. For us, this is the power source for so many of our devices, which makes understanding its risks so personal.

Internal Short Circuits

One of the primary drivers of thermal runaway in lithium-ion batteries is an internal short circuit. This can occur due to manufacturing defects (e.g., dendrite growth between electrodes, foreign metallic particles), mechanical damage, or degradation of the separator material. When a short circuit occurs, a large current flows through a low-resistance path, generating substantial heat.

Overheating and Thermal Abuse

Exposure to external heat sources, such as direct sunlight or proximity to other heat-generating devices, can raise the battery’s temperature to a critical point. This elevated temperature can accelerate parasitic reactions within the battery, leading to gas generation and swelling, and eventually to thermal runaway.

Chemical Reactors: Controlling the Reactions

In industrial chemical processes, managing exothermic reactions is paramount. Failures in controlling these reactions can have severe consequences.

Runaway Polymerization

Certain polymerization reactions are highly exothermic. If the cooling systems fail or if the initiator is added too quickly or at too high a concentration, the heat generated can exceed the system’s capacity to dissipate it, leading to a rapid and uncontrolled increase in temperature and pressure.

Decomposition Reactions

Many substances can undergo exothermic decomposition reactions when heated. If these reactions are not adequately controlled, they can escalate into a thermal runaway event. This is particularly relevant in the storage and handling of potentially unstable chemicals.

Electrical Components: Overheating and Failure

Beyond batteries, many other electrical components are susceptible to thermal runaway if they overheat.

Resistors and Capacitors

Certain types of resistors and capacitors can fail catastrophically if they exceed their temperature ratings. Overloading or internal defects can cause them to overheat, leading to a chain reaction.

Power Semiconductors

Components like transistors and diodes in power electronics can generate significant heat during operation. If cooling is insufficient or if the component is subjected to excessive current or voltage, it can overheat and enter thermal runaway, often leading to permanent damage and potentially fire.

Prevention Strategies: Building in Safety

Fortunately, thermal runaway is not an insurmountable problem. A combination of careful design, robust manufacturing, and vigilant monitoring can significantly mitigate the risks. These are the proactive measures that ensure our technologies remain safe and reliable.

Design and Material Selection

The foundational step in preventing thermal runaway lies in the initial design of a system and the careful selection of its constituent materials.

Thermal Management Systems

Effective thermal management is critical. This includes designing systems with adequate surface area for heat dissipation, incorporating heat sinks, fans, or liquid cooling systems to efficiently remove excess heat. The goal is to ensure that the rate of heat dissipation always exceeds or matches the rate of heat generation under normal and anticipated fault conditions.

Material Properties

Choosing materials with appropriate thermal conductivity, electrical resistance, and stability at operating temperatures is essential. For example, using flame-retardant materials in battery casings or selecting electrolytes with higher thermal stability in batteries can enhance safety.

Fail-Safe Mechanisms

Incorporating fail-safe mechanisms into the design can prevent runaway events. This could include fuses that blow at a specific current, circuit breakers that interrupt power flow, or thermal cut-off switches that disable the device if it overheats.

Manufacturing and Quality Control

Stringent manufacturing processes and rigorous quality control are vital to catch potential issues before they can lead to a runaway event.

Process Monitoring

Monitoring key parameters during manufacturing, such as curing times, mixing ratios, and assembly tolerances, helps ensure consistency and prevent defects that could initiate thermal runaway.

Inspection and Testing

Thorough inspection of finished products, including non-destructive testing methods, can identify flaws that might not be apparent to the naked eye. Similarly, rigorous testing under various operating conditions can reveal weaknesses in the design or manufacturing.

Purity and Contamination Control

Maintaining high levels of purity in raw materials and implementing strict procedures to prevent contamination during the manufacturing process are critical, especially in sensitive applications like battery production.

Thermal runaway is a critical phenomenon that can occur in various electronic devices, leading to catastrophic failures if not properly managed. For a deeper understanding of this issue and its implications in manufacturing processes, you might find it helpful to explore a related article on the topic. This article discusses the importance of proper thermal management in electronic components, which can be crucial in preventing incidents of thermal runaway. To read more about this, visit this link.

Monitoring and Response: Early Detection and Mitigation

| Parameter | Description | Typical Values / Range | Units |

|---|---|---|---|

| Onset Temperature | Temperature at which thermal runaway initiates | 80 – 150 | °C |

| Heat Generation Rate | Rate of heat produced during runaway reaction | 10 – 1000 | W/kg |

| Critical Heat Flux | Minimum heat flux to sustain thermal runaway | 5 – 50 | kW/m² |

| Reaction Activation Energy | Energy barrier for exothermic reaction | 50 – 200 | kJ/mol |

| Time to Thermal Runaway | Duration from initial heating to runaway | Seconds to minutes | Time |

| Maximum Temperature | Peak temperature reached during runaway | 200 – 1000+ | °C |

| Pressure Increase | Pressure rise due to gas generation | Up to several MPa | MPa |

| Material Type | Common materials prone to thermal runaway | Lithium-ion batteries, polymers, explosives | N/A |

Even with the best preventative measures, it’s prudent to have systems in place for monitoring and responding to conditions that could lead to thermal runaway. It’s like having a smoke detector in your home – it won’t prevent a fire from starting, but it will alert you to its presence early.

Real-time Monitoring

Implementing sensors to continuously monitor critical parameters like temperature, voltage, and current can provide early warnings of developing problems. This allows for intervention before a runaway event escalates.

Temperature Sensing

Placing temperature sensors at strategic locations within a system can detect localized overheating. This data can be used to trigger alarms or initiate shutdown procedures.

Voltage and Current Monitoring

Monitoring voltage and current in electrical systems can reveal anomalies that might indicate an impending short circuit or overload condition.

Alert Systems and Automatic Shutdowns

When monitoring systems detect abnormal conditions, it’s crucial to have a response plan.

Alarm Generation

Audible and visual alarms can alert operators to a developing issue, giving them time to take manual corrective action or evacuate if necessary.

Automatic Shutdowns

In critical systems, automatic shutdown procedures can be programmed to activate when predefined thresholds are exceeded. This can quickly de-energize the system and prevent further escalation, often averting a catastrophic failure.

Emergency Procedures and Mitigation

In the unfortunate event that thermal runaway commences, having well-defined emergency procedures can minimize damage and protect personnel.

Fire Suppression

For systems that pose a fire risk, having appropriate fire suppression systems in place (e.g., inert gas systems, specialized fire suppression agents for batteries) is crucial.

Containment

In some cases, the design may include features for containing the effects of a thermal runaway event, such as blast-resistant enclosures or vent systems to safely release pressure and gases.

By understanding the fundamental mechanisms of thermal runaway, recognizing its diverse triggers, and implementing comprehensive prevention and monitoring strategies, we can continue to safely harness the power of these technologies in our increasingly complex world.

Give us a call to discuss your next project

FAQs

What is thermal runaway?

Thermal runaway is a condition where an increase in temperature causes a further increase in temperature, often leading to a destructive result. It occurs when a system generates heat faster than it can dissipate, causing a self-accelerating reaction.

In which devices or systems does thermal runaway commonly occur?

Thermal runaway commonly occurs in batteries (especially lithium-ion batteries), electronic circuits, chemical reactors, and nuclear reactors. It is a critical safety concern in these systems due to the risk of fire or explosion.

What causes thermal runaway in lithium-ion batteries?

Thermal runaway in lithium-ion batteries is typically caused by internal short circuits, overcharging, physical damage, or exposure to high temperatures. These factors can lead to rapid heat generation and decomposition of battery materials.

How can thermal runaway be prevented?

Prevention methods include proper battery management systems, temperature monitoring, using thermal barriers, ensuring adequate cooling, and following safe charging and operating procedures. Design improvements and protective circuitry also help mitigate risks.

What are the consequences of thermal runaway?

Consequences can include fires, explosions, release of toxic gases, and damage to equipment or property. In severe cases, thermal runaway can pose serious safety hazards to people nearby.