Potting, Encapsulation, and Casting

Potting

Our Potting Services

Potting electronics refers to the process of covering a complete electronic assembly with an adhesive. Performing the potting process on electronics will stop corrosion of metals, shortages, and reduce damage caused by vibration and mechanical stress.

Common materials used for potting include thermosetting plastics, silicone rubber gels, and epoxy resins. These compounds harden, permanently protecting the assembly.

These materials vary in hardness from soft gels to hard plastics and are designed to withstand many specific types of environments. Some have excellent thermal conductivity while others have outstanding chemical or moisture resistance and all these materials provide good dielectric properties and have a wide range of additional properties to select from.

Features & Benefits

- Protection: Potting helps exclude water, moisture, and corrosive agents, safeguarding the components from environmental damage.

- Shock and Vibration Resistance: The compound increases resistance to shocks and vibrations, making the assembly more robust.

- Gaseous Phenomena Prevention: Potting prevents issues like corona discharge in high-voltage assemblies.

- Reverse Engineering Protection: It can also deter reverse engineering efforts.

- Low Cost: Potting can be one of the lowest cost options to seal your electronic components from the surrounding environment.

Potting Services We Provide

Potting Material Selection & Testing

Prototype Design & Fabrication

Production Potting

Vacuum & Pressure Potting

Encapsulation

Our Encapsulation Services

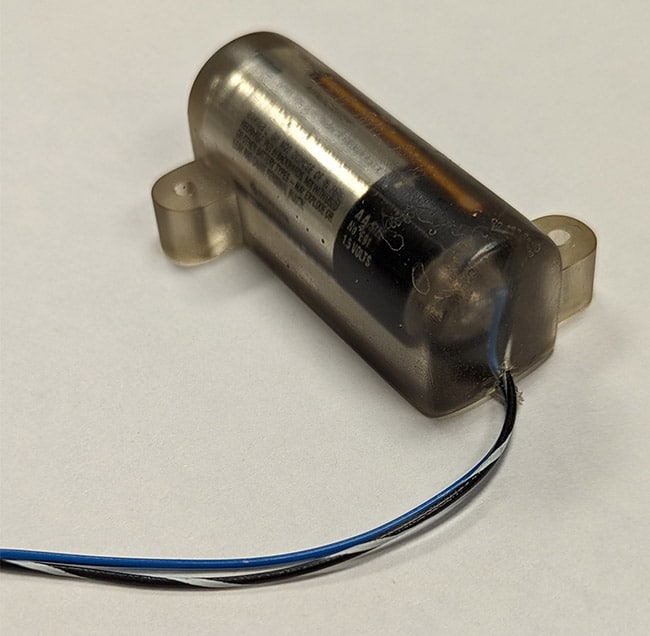

Encapsulation is very similar to potting in a plastic shell although instead of having a shell injection molded we can replace the shell with a reusable mold.

The encapsulation process works well with low to medium volumes because a meter mix dispense machine can be used for filling the molds but is not necessary.

The materials that we use with the encapsulation process are polyurethane, epoxy and silicones which are processed at room temperature or slightly elevated.

We will be glad to work with you from the initial stages of the product design.

Benefits of Potting & Encapsulation

- Low-Cost Shells or Molds

- Wide Range of Materials

- Low/High Volumes

- Hermetic-like Seal

- Low Pressure / Low Temperature

- Good Electrical Insulating Properties

- Safe for Delicate Components

- Can Withstand Environmental Extremes